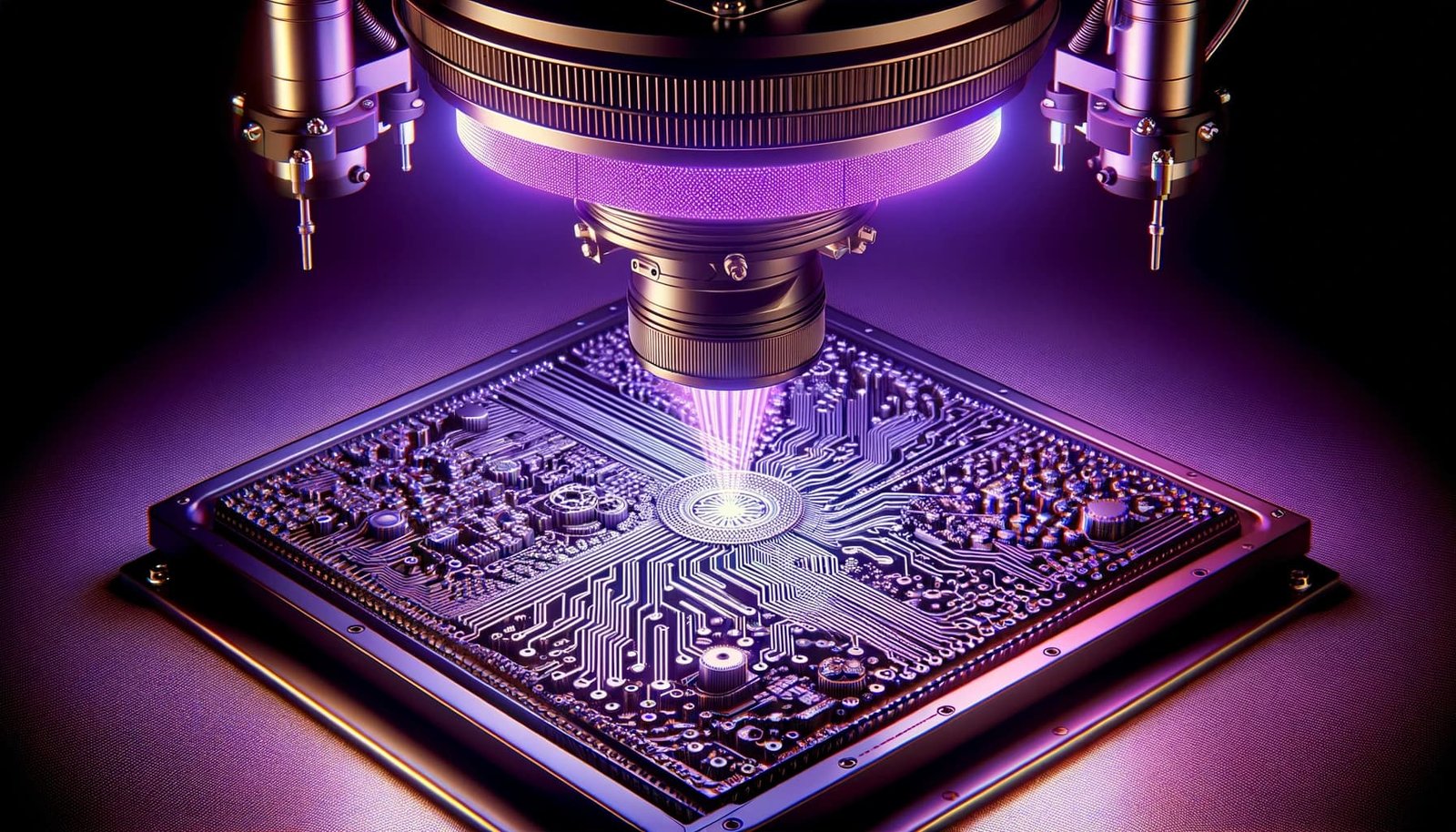

At Optomec, a leader in additive manufacturing solutions, my project focused on the development of innovative drivers for UV curing and aesthetic lighting within our additive manufacturing processes. This initiative was aimed at enhancing the efficiency and quality of our manufacturing systems, as well as improving the user experience through the integration of aesthetic lighting solutions.

Enhancing Efficiency with UV Curing

The core of this project involved the creation of advanced drivers for UV curing systems. UV curing is a critical step in many additive manufacturing processes, where it is used to rapidly solidify photopolymer resins into solid parts. By developing more efficient and precise control systems for UV light exposure, we were able to significantly improve the speed and quality of the curing process, leading to stronger and more accurate final products.

Adding Value with Aesthetic Lighting

Beyond the functional improvements, we also focused on the integration of aesthetic lighting into our manufacturing systems. This aspect of the project was designed to enhance the user interface and experience, making the additive manufacturing process more visually engaging and easier to monitor. The aesthetic lighting not only added to the visual appeal of our systems but also served as an intuitive indicator of the printing process’s status and progress.

Technologies and Impact

The development of these drivers required a deep understanding of both UV light technology and the specific requirements of additive manufacturing processes. The project leveraged cutting-edge software development tools and hardware integration techniques to create a seamless and efficient solution.

The introduction of enhanced UV curing capabilities and aesthetic lighting into Optomec’s additive manufacturing systems represented a significant advancement in our technology’s functionality and user experience. These innovations not only improved the quality and efficiency of our manufacturing processes but also set a new standard for design and usability in the industry.