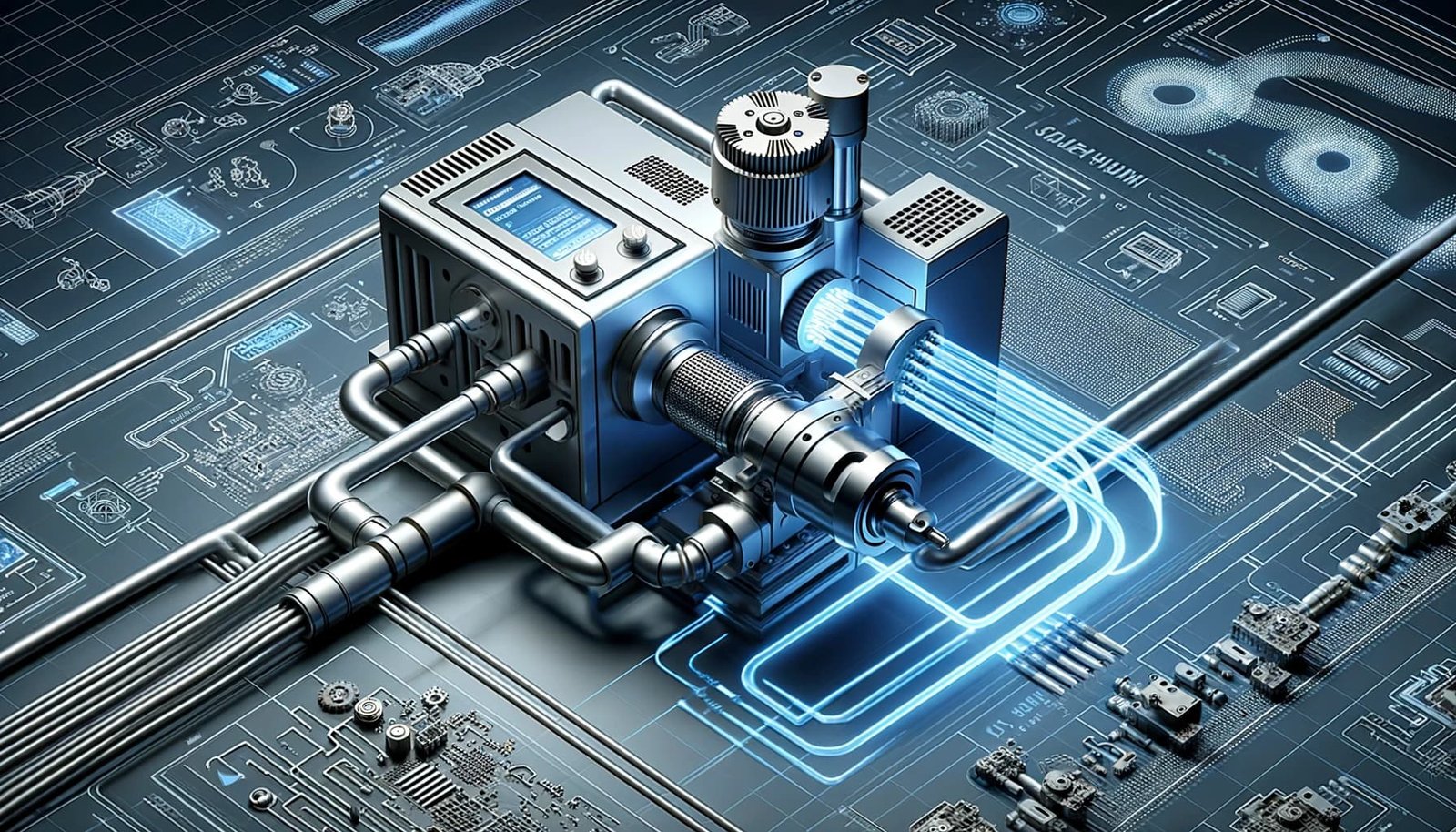

At Optomec, a pioneer in additive manufacturing technologies, I played a pivotal role in enhancing the efficiency and reliability of our aerosol jet systems. My project focused on the development of drivers for chiller control systems, a crucial component for regulating temperatures in ultrasonic atomization controllers. This advancement was instrumental in preventing our high-powered material atomizers from overheating, ensuring the seamless operation of our manufacturing processes.

The Challenge: Managing Heat in Material Atomization

The material atomization process is central to the functionality of Optomec’s aerosol jet systems. However, the high energy required for atomization poses a significant risk of overheating, which can compromise system integrity and product quality. The challenge was to create a robust solution that could maintain optimal temperatures, ensuring the reliability of the atomization process under continuous operation.

The Solution: Advanced Chiller Control Systems

To address this, I developed sophisticated drivers for chiller control systems designed to work seamlessly with ultrasonic atomization controllers. The key features of this system included:

- Precise Temperature Regulation: Implementing advanced algorithms to monitor and adjust the cooling output, ensuring the atomizers remained within safe operating temperatures.

- Enhanced System Integration: Ensuring the chiller control drivers were fully compatible with Optomec’s existing aerosol jet systems, allowing for easy implementation and minimal disruption to manufacturing processes.

- Reliability and Efficiency: The new chiller control systems not only prevented overheating but also optimized energy use, contributing to the overall efficiency and sustainability of the manufacturing process.

Impact and Legacy

The introduction of these chiller control systems marked a significant milestone in Optomec’s pursuit of excellence in additive manufacturing. By safeguarding our material atomization process from the risks of overheating, we were able to enhance the reliability and quality of our aerosol jet systems. This project underscored the importance of innovative cooling solutions in high-performance manufacturing environments and solidified my contribution to advancing Optomec’s technological capabilities.