At Optomec, a leader in advanced manufacturing solutions that utilize additive manufacturing technology, I had the opportunity to significantly enhance the effectiveness of both manufacturing and research efforts. My contribution centered on the development of a pivotal tool designed to generate system configurations based on end-user specifications. This innovation marked a major leap forward in how clients and staff interacted with our 3D printing systems.

Bridging User Needs with Technical Capabilities

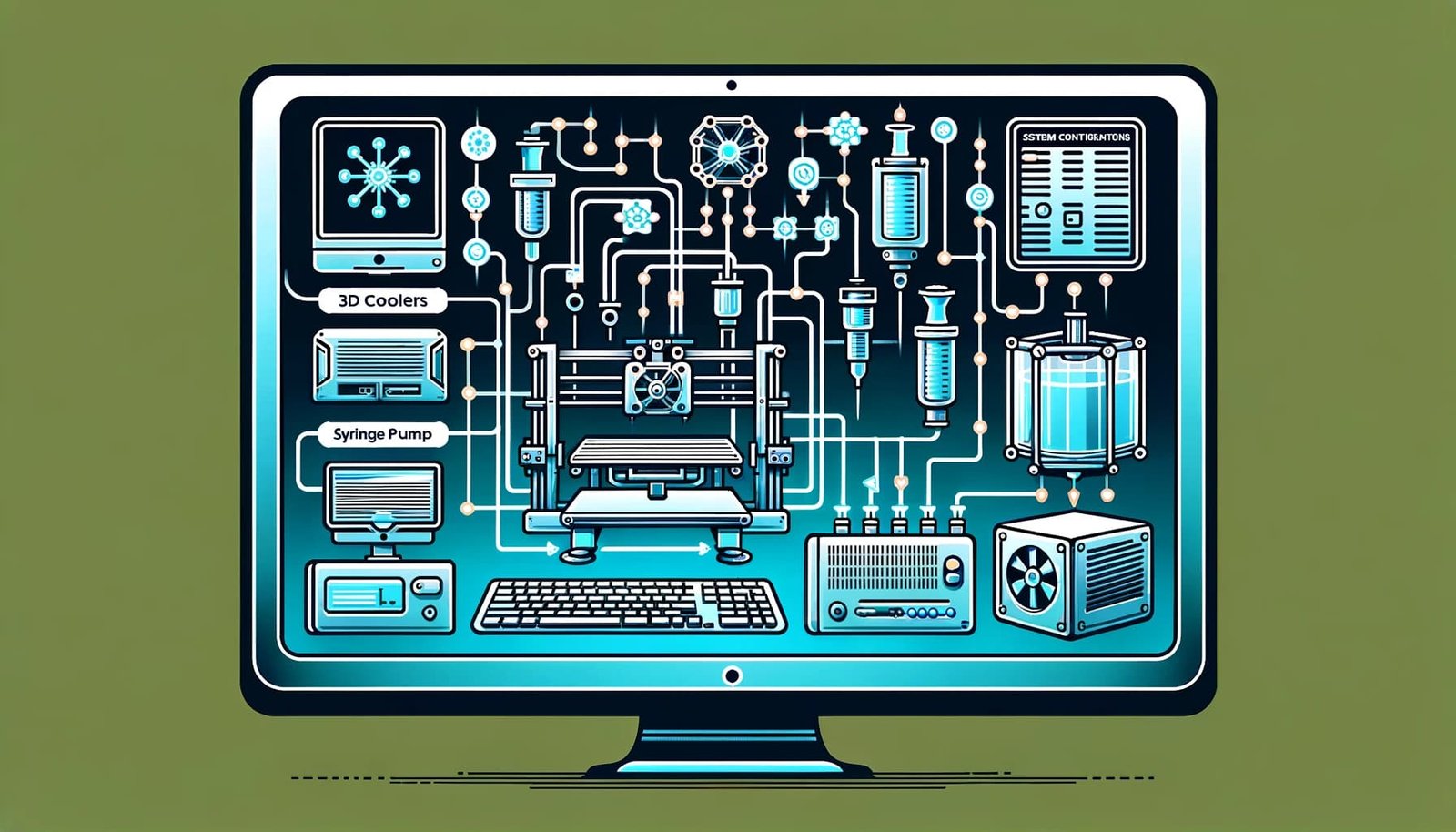

The challenge was to create an interface that could seamlessly translate user-defined hardware setups into precise configuration data necessary for the operation of 3D printing systems. The goal was to ensure that this configuration data would enable the native software to establish correct communication protocols with all on-system devices, including coolers, UV curing systems, syringe pumps, and motion controllers.

The Solution: A User-Centric Configuration Tool

The solution was a user-friendly tool that empowered clients and staff to specify their unique hardware requirements. This tool was meticulously designed to:

- Simplify Complex Configurations: By providing an intuitive interface, the tool made it straightforward for users to define their specific hardware setups without deep technical knowledge.

- Generate Precise Configuration Data: The tool automatically converted user inputs into detailed configuration data, ensuring that the 3D printing systems could recognize and correctly communicate with each connected device.

- Facilitate Efficient Operation: With accurate configuration data, the systems could operate more efficiently, reducing setup times and minimizing the potential for errors during printing processes.

Technologies and Impact

The development of this configuration tool involved integrating various technologies, including software development frameworks and communication protocols, to ensure compatibility with a wide range of hardware devices. By bridging the gap between user needs and technical capabilities, this tool not only enhanced the operational efficiency of Optomec’s 3D printing systems but also significantly improved the user experience for both clients and staff.

Legacy of Innovation

This project underscored the importance of user-centered design in the development of technical solutions. It demonstrated how thoughtful software tools could streamline complex processes, making advanced manufacturing technologies more accessible and effective. My time at Optomec was marked by this significant contribution, which not only advanced the company’s technological offerings but also reinforced my commitment to creating solutions that address real-world challenges in the manufacturing sector.